Aftermarket Excavator Components: A Cost-Effective Remedy for Your Excavator

Wiki Article

How Aftermarket Excavator Parts Can Improve Your Building and construction Tools's Efficiency

In the world of building devices maintenance, the choice between initial tools maker (OEM) parts and aftermarket alternatives can considerably impact the efficiency and performance of excavators. While OEM parts are widely identified for their quality and compatibility, aftermarket excavator components have actually been acquiring traction for their cost-effectiveness and potential advantages.Cost-efficient Alternatives for OEM Components

When seeking cost-effective alternatives for OEM components in the building and construction devices industry, it is essential to meticulously examine the top quality and compatibility of aftermarket alternatives. While OEM parts are understood for their exact fit and top quality, they typically feature a costs price. Aftermarket excavator parts use a more economical remedy without compromising on efficiency.To make certain that aftermarket parts are an ideal option, construction devices supervisors must assess the track record of the aftermarket producer. Trusted aftermarket distributors produce components that go beyond or satisfy OEM criteria, offering a cost-efficient choice without giving up quality. Furthermore, compatibility with the details make and model of the devices is crucial to prevent functional concerns and potential security threats.

Improved Performance and Productivity

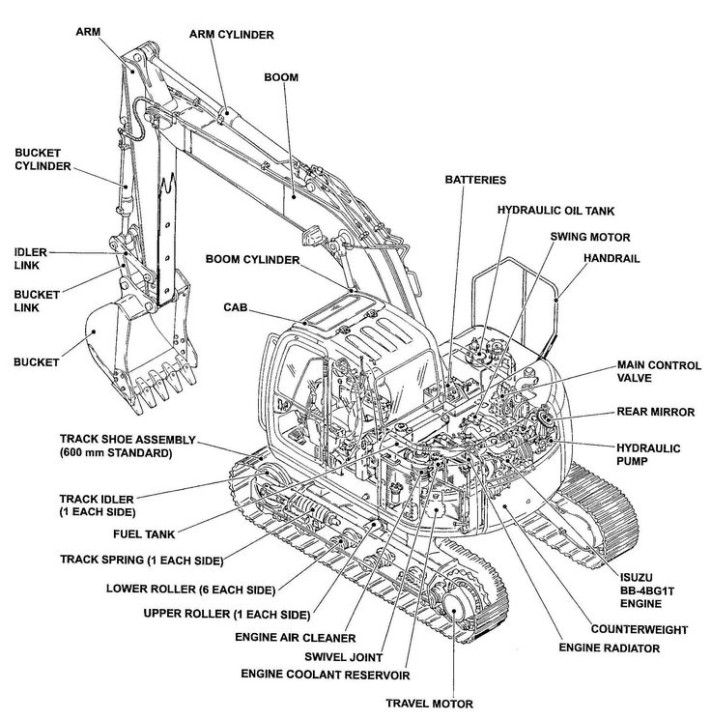

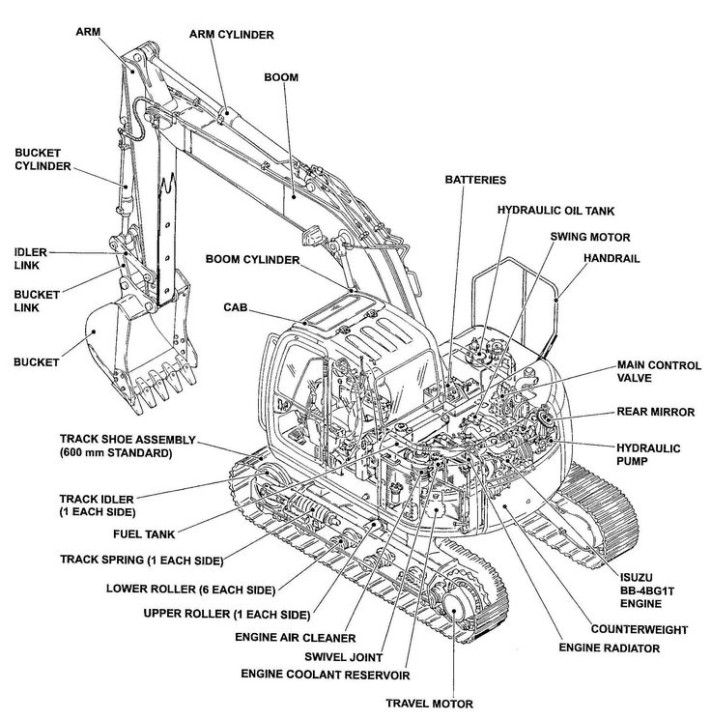

To take full advantage of operational efficiency and boost building and construction devices abilities, buying aftermarket excavator components not just supplies a cost-efficient remedy but additionally adds to enhanced performance and efficiency. Aftermarket parts are made to fulfill or surpass OEM specs, guaranteeing top quality and dependable efficiency. By replacing damaged or ineffective components with aftermarket choices, building equipment can run at optimal degrees, resulting in raised efficiency on the work site.Better performance is a key advantage of making use of aftermarket excavator parts. These parts are typically engineered with advanced technologies and materials, boosting the total effectiveness and performance of the devices (aftermarket excavator parts). Whether it's updating hydraulic systems, pail teeth, tracks, or various other vital parts, aftermarket parts can help increase the excavator's efficiency capabilities, enabling for smoother operations and faster cycle times

In addition, the improved productivity accomplished through aftermarket excavator components converts to cost savings and enhanced task timelines. With tools running much more effectively and effectively, building companies can finish jobs quicker, handle even more projects, and inevitably increase their bottom line. By buying aftermarket parts, building devices can reach its complete possibility, providing remarkable efficiency and driving general productivity.

Extended Life-span of Excavator Elements

The durability and durability of excavator elements can be substantially expanded via the use of top notch aftermarket parts. Buying aftermarket excavator components that are particularly developed to exceed the efficiency or meet of original devices producer (OEM) elements can lead to an extra durable and resistant construction equipment fleet. Aftermarket parts are often crafted with advanced products and manufacturing processes that improve their sturdiness, making them much more resistant to put on and tear sought after building settings.Boosted Equipment Dependability and Longevity

By enhancing the reliability and toughness of construction equipment, aftermarket excavator parts that outshine OEM elements contribute to a more resistant fleet qualified of holding up against the rigors of demanding construction environments. Aftermarket parts are often produced using advanced modern technologies and top quality products, causing enhanced equipment long life and reduced downtime. These elements are developed to go beyond or meet OEM specifications, making certain have a peek here a greater level of efficiency and dependability in the area.The enhanced integrity and toughness supplied by aftermarket excavator components translate right into expense financial savings for construction business. With reduced equipment failings and the demand for fewer repair services, services can operate more efficiently and maximize their productivity. In addition, the boosted toughness of these components means that construction equipment can sustain extreme working conditions without compromising efficiency.

Enhancing Building Tasks With Aftermarket Components

Enhanced building and construction job effectiveness can be accomplished via the calculated combination of high-performance aftermarket excavator components. additional resources By utilizing aftermarket components that are particularly created to enhance the efficiency of building devices, project supervisors can enhance different aspects of their construction jobs. These aftermarket components are engineered to boost the capability and performance of excavators, causing smoother operations and boosted effectiveness on duty website.One secret benefit of incorporating aftermarket excavator components into building and construction tasks is the capacity for faster completion times (aftermarket excavator parts). Upgraded components such as top notch hydraulic cyndrical tubes, precision-engineered pails, and resilient undercarriage parts can aid expedite tasks and enhance procedures. This effectiveness not only conserves time but also lowers labor expenses and lessens downtime, ultimately adding to total project success

Verdict

To conclude, aftermarket excavator components use an economical choice to OEM parts while offering enhanced efficiency, productivity, and extending the life-span of equipment elements. By making use of aftermarket components, construction devices integrity and toughness can be enhanced, leading to optimized building and construction projects. Take into consideration integrating aftermarket components into your building and construction equipment upkeep and repair techniques to make the most of effectiveness and efficiency at work website.In the world of building and construction equipment upkeep, the selection in between original tools producer (OEM) components and aftermarket alternatives can go to my site considerably impact the efficiency and efficiency of excavators. While OEM components are widely recognized for their top quality and compatibility, aftermarket excavator parts have been getting grip for their cost-effectiveness and possible advantages.To make sure that aftermarket components are an ideal option, construction devices managers need to examine the track record of the aftermarket supplier.By boosting the integrity and resilience of construction tools, aftermarket excavator parts that outshine OEM parts contribute to a more resistant fleet qualified of holding up against the rigors of demanding construction settings.In final thought, aftermarket excavator parts offer a cost-effective alternative to OEM components while offering enhanced efficiency, efficiency, and prolonging the life-span of devices elements.

Report this wiki page